Time: 2025-08-11 06:55:59 Source: Cangzhou Carbon Technology Co., Ltd.

To extend the service life of a vacuum furnace graphite rack, you need to focus on preventive maintenance, proper handling, and material selection. The primary causes of degradation are oxidation, thermal shock, and physical damage.

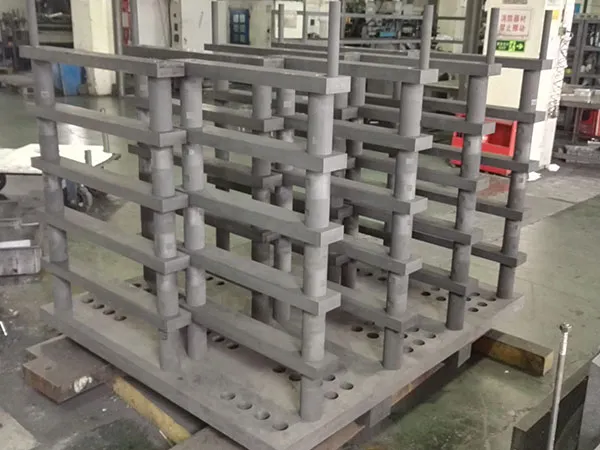

The service life of a graphite rack starts with the materials used and the design. While standard graphite is a good choice, carbon fiber composite (CFC) is often a superior material for racks and fixtures. CFC is made of carbon fibers in a carbon matrix, offering higher strength and rigidity, and is more resistant to fracture than basic graphite.

Carbon Fiber Composite (CFC): This material is lightweight, strong, and highly resistant to warping or distortion under high temperatures. Its lower thermal expansion helps prevent cracking caused by thermal cycling.

Coatings: Applying a protective coating, such as a silicon carbide-based graphite coating, can significantly extend the life of the rack by protecting it from wear, oxidation, and corrosion. This is especially useful in environments where there's a risk of contaminants.

Design for Durability: Choose rack designs that minimize stress points and allow for even heat distribution. Machining holes into plates or using specific fixtures can help with cooling and prevent distortion.

Proper handling and a consistent maintenance schedule are crucial for extending the life of your graphite rack.

Preventative Maintenance:

Daily Inspection: Visually inspect the rack daily for any signs of damage, such as cracks, broken pieces, or loose fasteners. Replace damaged components promptly.

Weekly Inspection: Hand-tighten nuts, bolts, and connectors to prevent arcing, which can burn away parts of the hot zone and degrade the rack. Avoid over-tightening, as this can break graphite elements.

Cleanup Cycles: Regularly run cleanup cycles to remove contamnants from the hot zone. Discoloration on heating elements and shields is a key indicator of contamination, which can cause accelerated degradation.

Avoid Physical Shock: Handle the rack carefully during loading and unloading to prevent dropping or chipping. Graphite is brittle and can be easily damaged by impact.

Control Temperatures: Operating the furnace at the lowest effective temperature and with a slow heating rate can reduce thermal stress on the graphite components. Graphite's strength increases with temperature up to a point, but excessive temperatures can still lead to faster degradation.

Minimize Air Exposure: Never open the vacuum chamber until the temperature is below 200°C. Graphite oxidizes rapidly in air at elevated temperatures, which can severely shorten its lifespan.

Keep it Clean: Regularly clean the rack and the entire chamber to remove any residues or particulates that could contaminate the graphite or cause reactions during a cycle. If cleaning is required, use deionized water, blow dry with nitrogen, and bake out the moisture before use. For stubborn residues, methanol can be used.

The cooling phase is just as critical as the heating phase.

Cool Under Vacuum: Allow the furnace to cool under vacuum to below the oxidation temperature (e.g., below 300°C / 572°F) before backfilling with gas or opening the door.

Avoid Rapid Gas Quenching: If your process involves a rapid gas quench, be aware this is extremely stressful for graphite. If possible, slow the quench rate or allow the load to cool naturally for a period before starting the quench.

Wait Until Cool to Unload: Do not unload the rack while it is still very hot. Hot graphite is more susceptible to mechanical damage. Wait until it is cool enough to handle safely.

Proactive care will significantly extend the life of your rack.

Regular Cleaning: After use, clean the rack to remove any debris or residue.

Use a soft brush, a vacuum cleaner with a soft attachment, or clean, dry compressed air.

Crucially, do not use water or solvents. If graphite absorbs moisture, it will turn into high-pressure steam inside the graphite pores during the next heat cycle, causing it to spall or crack.

Periodic "Dry-Out" or "Bake-Out" Runs: Periodically run an empty, high-temperature, high-vacuum cycle. This helps to burn off any accumulated contaminants and drive out any absorbed moisture from the graphite, "reconditioning" it for service.

Inspect for Damage: Before each use, visually inspect the rack for:

Cracks: Pay close attention to corners and high-stress areas.

Chipping or Erosion: Look for signs of material loss.

Discoloration: White or ashy areas can indicate oxidation.

Keep a Log: Track the number of cycles for each rack. This helps you understand its typical lifespan in your process and allows you to predict when replacement might be needed, preventing an in-process failure.