Time: 2025-08-25 03:22:34 Source: Cangzhou Carbon Technology Co., Ltd.

Graphite and its advanced derivatives, like carbon-carbon composites (CFC), are indispensable materials in the modern heat treatment industry. Their unique combination of thermal, chemical, and physical properties makes them superior to metals and ceramics for many high-temperature applications. Heat treatment processes—such as annealing, hardening, brazing, sintering, and carburizing—rely on precise temperature control in highly demanding environments, conditions for which graphite is exceptionally well-suited.

Before diving into the applications, it's crucial to understand why graphite is the material of choice.

High-Temperature Stability: Graphite does not melt at atmospheric pressure; it sublimes at approximately 3,650°C (6,600°F). Its mechanical strength actually increases with temperature, peaking at around 2,500°C, a property unmatched by metals which weaken significantly as they get hotter.

Excellent Thermal Shock Resistance: Graphite can withstand rapid heating and cooling cycles without cracking or failing. This is due to its high thermal conductivity and very low coefficient of thermal expansion.

Chemical Inertness: In a vacuum or an inert/reducing atmosphere, graphite is extremely stable and does not react with most metals, alloys, or process gases, preventing contamination of the workpieces.

High Thermal Conductivity: It efficiently and uniformly transfers heat, which is critical for ensuring that all parts in a furnace load reach the same temperature at the same time.

Low Coefficient of Thermal Expansion (CTE): Graphite expands and contracts very little with temperature changes. This dimensional stability is crucial for fixtures and jigs that must hold parts to tight tolerances throughout a heat treatment cycle.

Machinability and Design Flexibility: Despite its hardness, graphite is easily machined into complex shapes, allowing for the creation of custom fixtures, heating elements, and intricate furnace components.

Lightweight: Graphite has a low density compared to refractory metals like molybdenum or tungsten, making furnace fixtures easier to handle and reducing the thermal mass of the furnace, which can lead to faster cycle times and energy savings.

Electrical Conductivity: This property allows graphite to be used directly as a resistive heating element, simplifying furnace design.

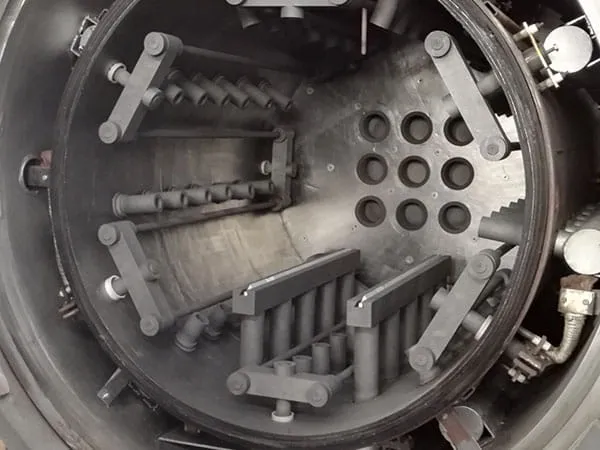

Graphite products are used extensively for both the internal components of the furnace ("the hot zone") and for the tooling that holds the workpieces.

1. Furnace Structural Components & Hot Zone

These are the core parts that make up the high-temperature environment of a vacuum or atmosphere furnace.

Heating Elements: Graphite is a common material for resistive heating elements. They can be machined into rods, plates, or complex cylindrical shapes that surround the workload, providing uniform radiant heat. They are a cost-effective and durable alternative to molybdenum or tungsten elements.

Hearth Plates, Rails, and Piers: These form the "floor" of the furnace hot zone, providing a stable, flat surface to support the heavy loads of workpieces. Graphite's high-temperature strength prevents it from sagging or warping under load.

Insulation:

Graphite Felt: A soft, flexible insulation material used as the primary thermal barrier in vacuum furnaces. It has extremely low thermal conductivity in a vacuum, is lightweight, and is easy to install.

Graphite Rigid Board (or Felt with CFC facing): For applications requiring more durability and erosion resistance (e.g., from high-velocity gas quenching), rigid graphite board or felt lined with a CFC sheet is used as the innermost hot-face insulation.

Nuts, Bolts, and Connectors: The entire hot zone is often assembled using threaded graphite fasteners. These maintain their clamping force at extreme temperatures where metal fasteners would fail.

2. Fixtures, Jigs, Grids, and Trays

These components are used to hold, position, and transport the parts being heat-treated.

Grids and Baskets: Used to hold large quantities of smaller parts. The lightweight nature of graphite allows for a higher payload of product versus fixture weight, improving efficiency. The design can be optimized for gas flow during quenching or carburizing.

Custom Fixtures and Jigs: For parts with complex geometries (e.g., turbine blades, automotive gears), custom-machined graphite fixtures are essential. They hold the parts in precise alignment to prevent distortion and warping during the heating and cooling cycle. Graphite's low CTE ensures the fixture and part expand and contract predictably.

Brazing Fixtures: In high-temperature vacuum brazing, graphite fixtures hold components together with precision. Its non-reactive surface prevents the braze alloy from sticking to the fixture.

Sintering Trays and Boats: In powder metallurgy, graphite trays are used to hold compacted metal powders during sintering. The material's stability ensures no contamination of the high-purity metal powders.

3. Process-Specific Components

Crucibles: Used for melting, holding, and processing metals and alloys in induction or resistance furnaces. Graphite's non-reactivity and thermal stability are critical here.

Susceptors: In induction heating, a non-conductive workpiece can be placed inside a graphite susceptor. The induction coil heats the graphite susceptor, which then radiates heat to the workpiece.

Degassing Rods and Tubes: In the production of molten aluminum and other metals, graphite rods or lances are used to bubble inert gas (like argon) through the melt to remove dissolved hydrogen, which improves the quality of the final casting.

Molds and Dies for Continuous Casting: Graphite's thermal stability, self-lubricating properties, and non-stick nature make it an excellent material for dies used in the continuous casting of metals like copper, brass, and precious metals.

Not all graphite is the same. The grade is chosen based on the specific application's demands.

Isostatic Graphite: High-density, high-strength, fine-grained graphite. It's ideal for complex machined parts like intricate fixtures, crucibles, and heating elements.

Extruded Graphite: A more economical grade, often used for larger, simpler shapes like support posts, rails, and large heating elements.

Carbon-Carbon Composite (CFC): The premium choice. It consists of a graphite matrix reinforced with carbon fibers. CFC is exceptionally strong, lightweight, and highly resistant to damage and erosion. It is the preferred material for high-wear applications like fixtures, grids, and hot-face insulation liners in furnaces with aggressive quenching.

Purified Graphite: For semiconductor and high-purity applications, graphite undergoes a purification process to remove ash and other contaminants that could outgas and compromise the process.

Limitations and Considerations

Oxidation: Graphite's primary weakness is its reaction with oxygen at elevated temperatures (starting around 450°C / 840°F). For this reason, graphite components are almost exclusively used in vacuum furnaces or furnaces with inert (e.g., Argon, Nitrogen) or reducing (e.g., Hydrogen) atmospheres.

Brittleness: While strong, graphite is a brittle material and can be damaged by mechanical impact. CFC significantly improves upon this, offering much greater fracture toughness.

Graphite products are the backbone of high-temperature heat treatment. From the very structure of the furnace hot zone to the intricate fixtures that hold mission-critical components, graphite's unparalleled performance at extreme temperatures ensures process reliability, part quality, and operational efficiency. The continuous development of advanced forms like Carbon-Carbon Composites further solidifies its role as the go-to material for the industry's most demanding challenges.