Time: 2025-09-02 09:26:06 Source: Cangzhou Carbon Technology Co., Ltd.

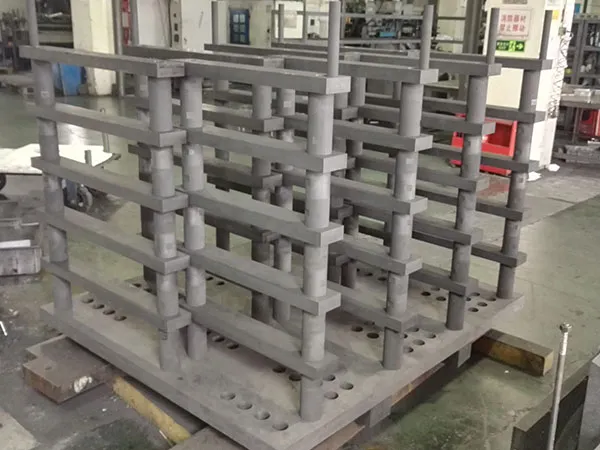

Graphite rack play a crucial role in vacuum furnaces, serving as stable supports for workpiecesduring high-temperature heat treatment processes. Due to their excellent thermal stability, chemicaresistance, and mechanical strength, graphite components are widely applied in aerospace,metallurgy, electronics, and new material industries. However, under long-term service conditionsinvolving extreme temperatures, vacuum environments, and repeated thermal cycing, graphitebrackets are prone to deformation.

Deformation of graphite rack not only affects the accuracy of workpiece positioning but alsoshortens equipment life and increases maintenance costs. The causes are often related to thermastress, material quality, improper loading, and operational factors. Understanding these causes isessential for improving furnace reliability and ensuring product quality.

Description: Graphite expands when heated and contracts when cooled. In a vacuum furnace, rapid heating and cooling cycles, or uneven heating, can create significant thermal stresses within the graphite. If different parts of the bracket heat or cool at different rates, they will expand or contract unevenly, leading to warpage and deformation.

Prevention:

Controlled Heating/Cooling Rates: Implement slow and controlled heating and cooling ramps in the furnace program. Avoid abrupt temperature changes, especially during the critical phases.

Uniform Heating: Ensure the furnace design provides uniform heating throughout the hot zone where the graphite brackets are located. Optimize element placement and insulation.

Material Selection: Use isotropic graphite grades, which have similar thermal expansion coefficients in all directions, reducing internal stresses during temperature changes.

Description: At very high temperatures (typically above 2000°C for graphite), materials can slowly deform under constant mechanical stress, even if the stress is below the material's yield strength. This phenomenon is known as creep. The weight of the parts being held by the bracket, combined with the high temperature, can cause the graphite to sag over time.

Prevention:

Design for Load Distribution: Design the brackets to distribute the load as evenly as possible and minimize stress concentrations. Use thicker sections or reinforce areas under high stress.

Intermittent Use or Rotation: If possible, rotate the brackets or use them intermittently to allow for stress relaxation and prevent continuous creep in one direction.

High-Strength Graphite: Utilize high-density, high-strength graphite grades specifically designed for high-temperature applications, which exhibit better creep resistance.

Description: While vacuum furnaces aim for a perfect vacuum, residual gases (like oxygen or water vapor) can still be present, especially if there are leaks or if materials outgas. Graphite reacts with oxygen at high temperatures, forming carbon monoxide or carbon dioxide, leading to material loss and weakening of the structure. This can cause localized thinning and subsequent deformation under load.

Prevention:

Maintain High Vacuum: Ensure the furnace system is leak-tight and maintain the best possible vacuum level.

Proper Bake-out: Thoroughly bake out the furnace chamber and any new materials to remove adsorbed gases and moisture.

Inert Gas Backfill: For critical applications, consider backfilling with high-purity inert gas (e.g., argon) during cooling, especially at temperatures where oxidation is a concern.

Protective Coatings: In some cases, applying a protective coating (e.g., SiC coating) to the graphite can enhance its oxidation resistance, though this adds complexity and cost.

Description: Graphite, being a manufactured material, can have inherent defects like pores, cracks, or variations in density and grain structure. These inhomogeneities can act as stress concentrators, leading to localized failure or uneven thermal expansion/contraction, promoting deformation.

Prevention:

Quality Graphite: Source high-quality, fine-grain, high-purity graphite from reputable manufacturers.

Inspection: Inspect new graphite components for visible defects before use.

Description: Some materials being processed in the furnace can react with the graphite at high temperatures, forming carbides or other compounds. This can alter the graphite's properties, weaken its structure, and lead to deformation.

Prevention:

Material Compatibility: Understand the chemical compatibility between the processed materials and graphite at elevated temperatures.

Protective Barriers: Use sacrificial layers or ceramic barriers between the processed parts and the graphite bracket if chemical reactions are a concern.

Proper Design: Design graphite brackets with sufficient thickness and structural integrity for the intended load and temperature. Consider finite element analysis (FEA) for complex designs.

Regular Inspection: Periodically inspect graphite components for signs of wear, cracks, or deformation. Replace them proactively if significant degradation is observed.

Documentation: Keep records of the operational life and performance of graphite components to track their lifespan and predict replacement cycles.

Material Upgrades: As furnace temperatures or loads increase, consider upgrading to higher-performance graphite grades or carbon-composite materials (e.g., Carbon-Carbon Composites, C-C) which offer superior strength-to-weight ratio and creep resistance at very high temperatures.

By understanding these causes and implementing the preventive measures, the lifespan and performance of vacuum furnace graphite brackets can be significantly improved, reducing downtime and maintenance costs.