Time: 2025-06-23 06:44:40 Source: Cangzhou Carbon Technology Co., Ltd.

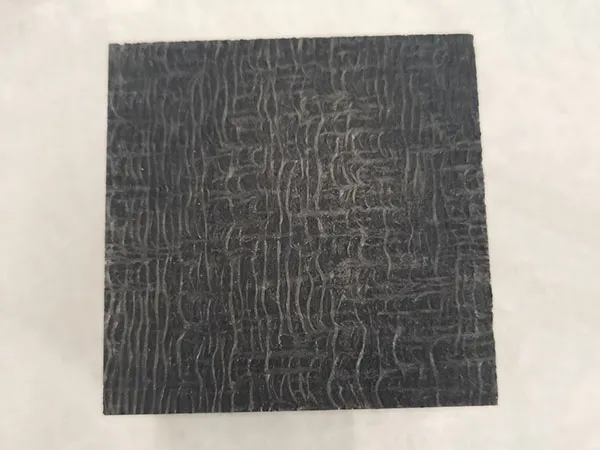

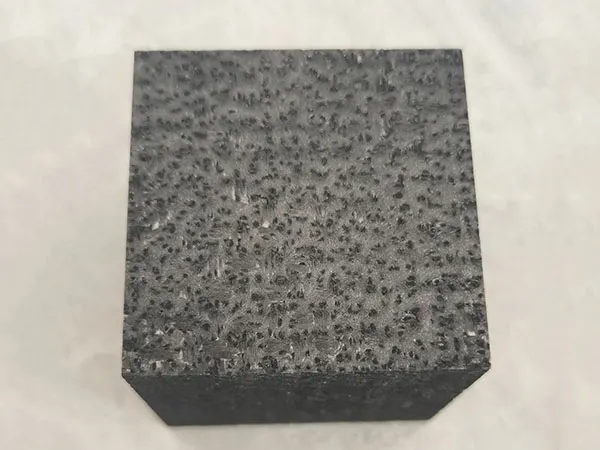

Carbon-Carbon (C/C) composites are a class of high-performance materials that stand at the pinnacle of engineering for extreme environments. Composed of carbon fibers embedded within a carbon matrix, they are renowned for one primary characteristic: their extraordinary ability to maintain and even increase their strength at extremely high temperatures.

High strength-to-weight ratio: They are incredibly strong yet lightweight.

Excellent high-temperature resistance: They can retain their mechanical properties at extremely high temperatures (up to 3000°C or even 3315°C in inert atmospheres).

High thermal conductivity: Efficiently dissipate heat.

Low thermal expansion coefficient: Resist changes in size with temperature fluctuations.

High fatigue resistance: Can withstand repeated stress without failure.

Biocompatibility: Suitable for use in the human body.

Chemical inertness: Resist corrosion from various chemicals.

Due to these remarkable characteristics, carbon-carbon composites find applications in a wide range of demanding industries:

1. Aerospace and Defense: This is the primary application area for C/C composites.

High-performance braking systems: Used extensively in aircraft (commercial and military, like the Concorde and Airbus A320) and high-speed vehicles (Formula One cars, supercars like Bugatti Veyron, and many Bentleys, Ferraris, Lamborghinis, Porsches). They offer superior heat capacity, reduced weight, and longer service life compared to steel brakes.

Re-entry heat shields and nose cones: Essential for spacecraft (like the Space Shuttle orbiter's nose cone and wing leading edges), missiles, and re-entry vehicles, protecting them from extreme temperatures generated during atmospheric re-entry.

Rocket nozzles and motor throats: Can withstand the immense heat and pressure of rocket propulsion.

Leading edges of high-performance aerospace vehicles: Areas subject to intense heat and friction.

Engine components: Parts of turbojet engines.

Aircraft structural components: Fuselage, wings, tail sections, doors, and interior parts, contributing to lighter and more fuel-efficient aircraft (e.g., Boeing 787 Dreamliner, Airbus A350-XWB).

2. Industrial Applications:

Heating elements: In high-temperature furnaces.

Hot-pressed dies and molds: For manufacturing processes requiring high temperatures and pressures.

Vacuum/inert gas furnace insulation: Providing thermal protection in extreme environments.

Metal sintering trays: Used in metal processing.

Protective shielding: In various high-temperature settings.

Electronic circuit board thermal planes: For efficient heat dissipation.

Semiconductor manufacturing components: Where high purity and temperature resistance are crucial.

3. Automotive:

High-performance vehicle components: Beyond brake systems, C/C composites are used in racing car parts and high-end road cars for their lightweight and strength, improving performance and fuel efficiency.

Engine pistons: For enhanced durability and performance.

4. Medical Field:

Biomedical implants: Such as artificial joints, skeletons, and heart components, due to their biocompatibility and strength.

Prosthetics and surgical tools: Where lightweight, strong, and biocompatible materials are needed.

5. Sporting Goods:

High-performance equipment: Including tennis rackets, golf clubs, hockey sticks, archery bows, skis, snowboards, wakeboards, kiteboards, rowing shells, and bicycle frames, offering lighter weight, increased stiffness, and improved performance for athletes.

While the high cost and susceptibility to oxidation (which necessitates protective coatings for many applications) have historically limited their widespread use, ongoing research aims to reduce fabrication costs and expand the applications of these remarkable materials.