Time: 2025-06-21 02:36:09 Source: Cangzhou Carbon Technology Co., Ltd.

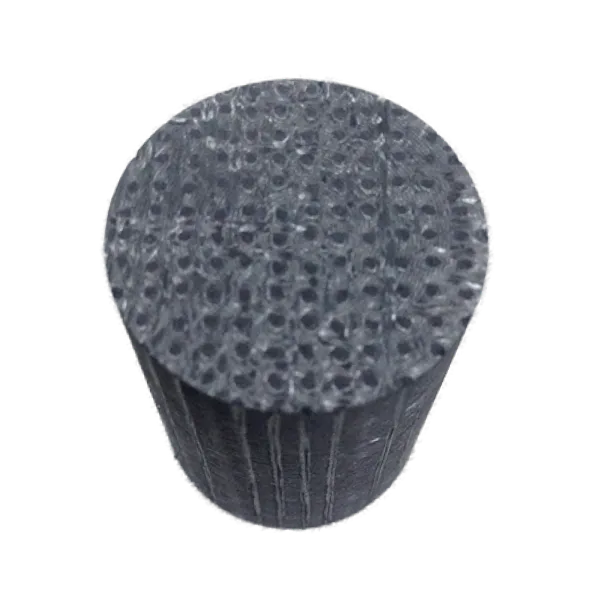

Carbon-carbon (C-C) composites are renowned for their exceptional thermal properties, which make them ideal for high-temperature and demanding applications such as aerospace components (e.g., brake discs for aircraft, rocket nozzles, re-entry nose tips) and industrial furnaces. These properties are highly dependent on the manufacturing process, fiber type, orientation, and matrix density.

High-Temperature Stability:

C-C composites retain their mechanical properties and dimensional stability at extremely high temperatures, often exceeding 2000℃(3632℉) and even up to 3000℃(5432℉) in non-oxidizing atmospheres. This is significantly higher than most metals and other advanced ceramics.

Their excellent thermal shock resistance is a major advantage, allowing them to withstand rapid and extreme temperature changes without significant damage.

Thermal Conductivity:

C-C composites can exhibit a wide range of thermal conductivities, from good insulators to excellent conductors, depending on their fabrication and microstructure. This "tailorable" conductivity is a significant advantage.

Anisotropy: Thermal conductivity is often anisotropic, meaning it varies with direction.

In-plane (along the fiber direction): Values can range from approximately $10 \text{ W/(m·K)}$ to $233 \text{ W/(m·K)}$. Graphitized fibers contribute to higher in-plane conductivity.

Through-the-thickness (perpendicular to the fiber direction): Values are typically lower, ranging from $2 \text{ W/(m·K)}$ to $21 \text{ W/(m·K)}$.

Temperature Dependence: Thermal conductivity generally decreases with increasing temperature, although values can be fairly stable at very high temperatures.

Compared to other materials: While a simple carbon fiber-epoxy composite might have thermal conductivity 40 times less than aluminum and 10 times less than steel, advanced C-C composites, particularly those with highly graphitized matrices, can achieve conductivities comparable to or even exceeding some metals.Coefficient of Thermal Expansion (CTE):

C-C composites generally possess a very low coefficient of thermal expansion, meaning they exhibit minimal dimensional changes when subjected to temperature fluctuations. This contributes to their excellent dimensional stability and thermal shock resistance.

Anisotropy: Like thermal conductivity, CTE in C-C composites is often anisotropic.

In the fiber direction, carbon fibers can even have a negative CTE, meaning they slightly contract when heated. This unique property, combined with the matrix, can result in very low or even near-zero overall CTE in certain directions.

Typical ranges for linear CTE are from approximately −1× 10⁻⁶ K-1to +8×10⁻⁶ K-1

The CTE is influenced by the fiber type, weave architecture, matrix density, and the degree of graphitization.Specific Heat Capacity:

The specific heat capacity of carbon-carbon composites is generally comparable to that of graphite, especially at temperatures above 340 K.

Typical values are around$760 \text{ J/(kg·K)}$ ($0.18 \text{ BTU/(lb·^\circ F)}$) at room temperature, which can increase with temperature.

The thermal properties of C-C composites are not fixed values but vary significantly based on:

Fiber type and architecture: The type of carbon fibers (e.g., PAN-based, pitch-based), their orientation (unidirectional, bi-directional, multi-directional weaves), and volume fraction all play a crucial role. Highly oriented and graphitized fibers lead to higher thermal conductivity in the fiber direction.

Matrix material: The carbon matrix, formed through processes like chemical vapor infiltration (CVI) or liquid phase infiltration (LPI) followed by pyrolysis, significantly affects properties. The microstructure of the matrix (e.g., rough laminar, smooth laminar, isotropic pyrolytic carbon) influences thermal conductivity and CTE.

Graphitization heat treatment: High-temperature graphitization (often above 2000℃) transforms amorphous carbon into crystalline graphite, which generally increases thermal conductivity and modulus of elasticity.

Density and porosity: Higher density and lower porosity typically lead to improved thermal conductivity and more consistent properties.

Fiber/matrix interface: A well-bonded interface facilitates heat transfer and contributes to the overall thermal performance of the composite.

In summary, carbon-carbon composites are unique materials with a combination of high-temperature stability, excellent thermal shock resistance, and a broad, tailorable range of thermal conductivity and thermal expansion properties, making them indispensable for extreme thermal environments.