Time: 2026-01-15 06:23:42 Source: Cangzhou Carbon Technology Co., Ltd.

Induction heating has become a critical technology across industries—from metal forging and heat treatment to advanced materials manufacturing and semiconductor processing. At the core of any efficient induction system lies the susceptor, the component that absorbs electromagnetic energy and converts it into heat. Selecting the right susceptor is essential for maximizing energy efficiency, ensuring process stability, and maintaining product quality. Two widely used materials in this field are graphite and ceramic, each with distinct advantages and limitations. But how do you choose the right one for your specific application? Let’s explore in detail.

A susceptor is not merely a passive part in an induction system—it directly interacts with the electromagnetic field to generate heat. When exposed to induction, the susceptor heats up and transfers energy to the workpiece. Its performance depends on several critical factors:

Electrical Conductivity: Determines how efficiently the material converts electromagnetic energy into heat.

Thermal Stability: Ensures consistent performance at high temperatures.

Chemical Resistance: Prevents degradation when exposed to reactive materials or harsh atmospheres.

The decision between graphite and ceramic often hinges on your process requirements, temperature range, and budget constraints.

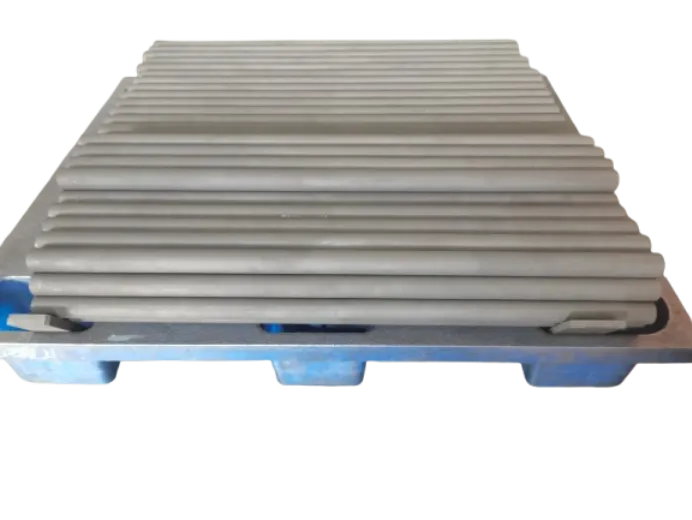

Graphite has been a staple in induction heating for decades. Its primary benefits include:

High Thermal Conductivity: Quickly spreads heat, providing uniform temperature across the workpiece, which is critical for metals and alloys.

Excellent Thermal Shock Resistance: Can handle rapid temperature changes without cracking, ideal for batch processing or cyclical heating.

Cost-Effective and Accessible: Lower upfront costs compared to advanced ceramics and widely available in various sizes.

Limitations to consider:

Oxidation at High Temperatures: In open-air applications, graphite may oxidize above 400–500°C, requiring inert atmospheres or protective coatings.

Shape Limitations: While machinable, complex geometries can be challenging compared to molded ceramics.

Applications: Graphite is ideal for metal melting, heat treatment, brazing, and general industrial induction heating where temperatures are moderate and oxidation can be controlled.

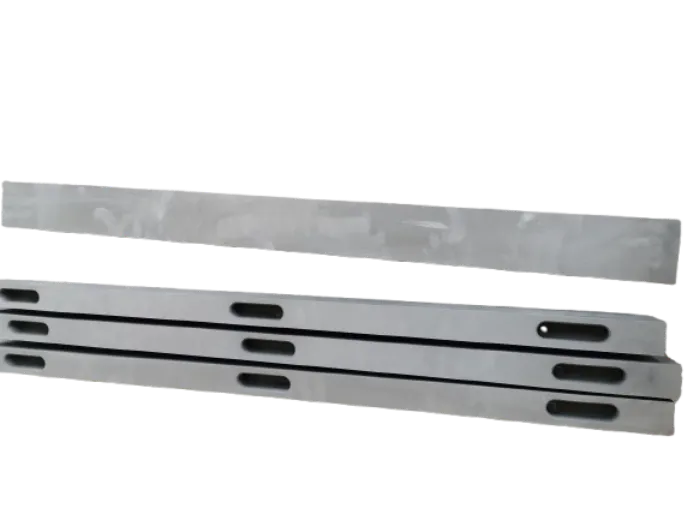

Ceramic susceptors are increasingly favored in high-temperature or chemically aggressive environments. Key advantages include:

Outstanding High-Temperature Stability: Can operate above 1000°C without structural degradation.

Chemical Inertness: Resistant to corrosion and oxidation, making them suitable for specialty materials and reactive metals.

Custom Shapes and Precision: Can be molded, cast, or 3D-printed for complex geometries.

Challenges:

Lower Thermal Conductivity: Heat may distribute less evenly, requiring careful process tuning.

Brittleness: Prone to cracking under mechanical stress or sudden thermal changes.

Higher Cost: Advanced ceramics involve higher material and fabrication expenses.

Applications: Ceramic susceptors excel in high-temperature sintering, chemical processing, and specialty alloy heating where stability and chemical resistance are priorities.

|

Feature |

Graphite |

Ceramic |

|

Thermal Conductivity |

High |

Moderate |

|

Thermal Shock Resistance |

Excellent |

Moderate |

|

Maximum Temperature |

~500–1000°C (with protection) |

>1000°C |

|

Chemical Resistance |

Limited |

Excellent |

|

Shape Flexibility |

Moderate |

High (moldable/3D-printable) |

|

Cost |

Low |

High |

When selecting a susceptor, consider the following factors:

Operating Temperature: Graphite suffices for moderate temperatures; ceramics are necessary for extreme heat applications.

Process Atmosphere: Oxidizing environments favor ceramics, while graphite needs inert or protective atmospheres.

Geometry Requirements: Complex or precise shapes often favor ceramic materials.

Thermal Uniformity: Graphite ensures rapid, uniform heating for metals; ceramics may need design optimization.

Budget Constraints: Graphite is cost-efficient; ceramics may require higher initial investment but offer longevity in harsh conditions.

Pro Tip: Some advanced induction systems combine both materials—using graphite for its thermal conductivity and ceramic coatings for oxidation resistance. This hybrid approach can deliver the best of both worlds.

Both graphite and ceramic susceptors offer unique advantages. Graphite provides cost-effective, fast, and shock-resistant heating, while ceramic ensures superior high-temperature and chemical stability. Choosing the right susceptor requires balancing process needs, environmental conditions, and budget considerations.

Investing in the right susceptor can improve energy efficiency, extend equipment lifespan, and enhance product quality, making it a critical decision for any manufacturer leveraging induction heating technology.

Next Steps for Manufacturers: Evaluate your process temperatures, workpiece materials, and operating environment before deciding. If needed, consult with susceptor suppliers for customized solutions that maximize both performance and ROI.