Time: 2025-12-05 06:16:32 Source: Cangzhou Carbon Technology Co., Ltd.

Continuous casting has become a core process in modern metal manufacturing, and graphite continuous casting molds play an indispensable role in ensuring stable production and high-quality metal outputs. With their unique thermal, mechanical, and chemical properties, graphite molds enable manufacturers to achieve greater efficiency, consistency, and cost savings. This article explores how graphite continuous casting molds work and how to optimize them for long-term performance.

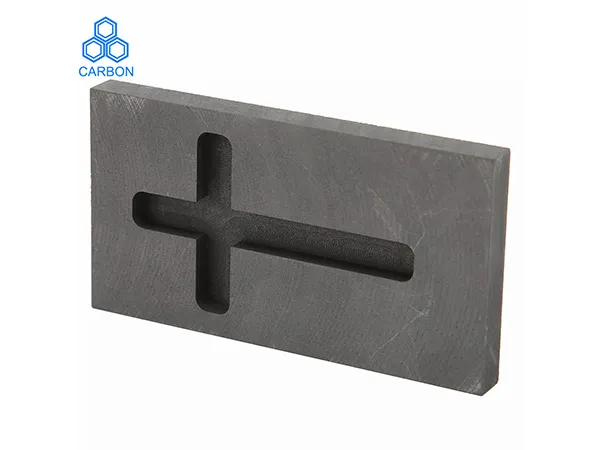

Graphite continuous casting molds are precision-engineered components made from high-density, fine-grain graphite materials. They are designed to shape molten steel, copper alloys, aluminum, and other non-ferrous metals into billets, rods, tubes, or other continuous profiles.

Compared with traditional molds made from copper or steel, graphite molds offer several distinct advantages:

Exceptional thermal conductivity for faster, more uniform cooling

Low friction and self-lubricating performance to reduce surface defects

High temperature and oxidation resistance, ideal for harsh casting environments

Minimal thermal expansion, ensuring dimensional accuracy

Longer service life, lowering the overall production cost

These characteristics make graphite molds a preferred choice for modern high-speed casting lines.

The working principle of graphite continuous casting molds centers around controlled cooling, continuous metal flow, and stable mold–metal interaction.

1. Molten Metal Feeding

Molten metal is poured into the inlet of the graphite mold at a precisely controlled temperature. Before casting begins, the mold is coated with a lubrication agent to reduce friction, prevent sticking, and protect the mold surface.

2. Heat Transfer and Initial Solidification

Graphite’s high thermal conductivity allows rapid heat absorption from the molten metal. As heat is extracted, a solidified metal shell begins forming along the mold wall while the interior remains partially molten.

This controlled thermal gradient is essential for creating a stable casting structure.

3. Continuous Shaping and Withdrawal

As the metal continues cooling, it gradually solidifies into the desired shape. A withdrawal mechanism pulls the semi-solid metal downward at a synchronized speed, creating a continuous, defect-minimized casting.

Proper alignment, withdrawal speed, and mold temperature control are critical to preventing cracks, shrinkage, or surface irregularities.

4. Lubrication and Mold Protection

Graphite molds are typically used with water-based, oil-based, or powder-type lubricants. These lubricants:

Improve heat transfer

Reduce metal–mold friction

Prevent carbon pickup

Protect the mold from thermal shock

Routine lubrication enhances both casting quality and long-term mold stability.

Several variables can affect casting efficiency, mold lifespan, and product quality:

1. Molten Metal Temperature

Excessive temperatures may accelerate mold oxidation or cause rapid erosion.

2. Cooling System Efficiency

Inconsistent or insufficient cooling leads to uneven solidification and dimensional instability.

3. Lubrication Quality

Poor lubrication increases sticking, friction, and mold surface wear.

4. Graphite Material Grade

Higher-density graphite with minimal impurities provides better thermal conductivity and structural strength.

5. Casting Speed

Overly fast withdrawal may cause cracks or incomplete solidification.

To maximize productivity and reduce maintenance downtime, manufacturers can adopt the following practices:

Select premium fine-grain graphite to enhance thermal stability and mold strength

Maintain uniform cooling water flow to promote consistent solidification

Apply the correct type of mold powder or lubricant for each metal grade

Monitor mold wear patterns and schedule preventive maintenance

Control metal pouring temperature within the recommended range

Ensure proper alignment between mold, cooling system, and withdrawal unit

Implementing these strategies can significantly improve casting quality while extending mold service life.

Understanding how graphite continuous casting molds work is crucial for any manufacturer aiming to improve output quality, raise efficiency, and reduce production costs. With superior thermal characteristics and resistance to extreme working conditions, graphite molds provide a reliable solution for continuous casting operations.

By selecting the right graphite materials, optimizing cooling systems, and maintaining consistent operating procedures, companies can achieve:

Higher production efficiency

More stable product quality

Reduced mold consumption

Greater long-term competitiveness

Investing in high-performance graphite continuous casting molds is not just a technical upgrade—it is a strategic step toward more efficient and future-ready metal production.